Break The Mold

News & Events

Magna is always making news in innovation, new product development and manufacturing. Please check here for latest updates:

🎯 𝑺𝒑𝒂𝒄𝒆 𝒇𝒐𝒓 𝒕𝒉𝒆 𝑭𝒖𝒕𝒖𝒓𝒆 🎉

🎯 𝑺𝒑𝒂𝒄𝒆 𝒇𝒐𝒓 𝒕𝒉𝒆 𝑭𝒖𝒕𝒖𝒓𝒆 🎉

As part of our strategic focus on 𝐟𝐮𝐭𝐮𝐫𝐞 𝐞𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧 and 𝐨𝐩𝐞𝐫𝐚𝐭𝐢𝐨𝐧𝐚𝐥 𝐞𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲, we are pleased to announce the 𝐞𝐬𝐭𝐚𝐛𝐥𝐢𝐬𝐡𝐦𝐞𝐧𝐭 𝐨𝐟 𝐨𝐮𝐫 𝐒𝐨𝐮𝐭𝐡 𝐂𝐚𝐦𝐩𝐮𝐬📍.

The South Campus is located 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 300 𝐦𝐞𝐭𝐫𝐞𝐬 𝐟𝐫𝐨𝐦 𝐭𝐡𝐞 𝐂𝐨𝐦𝐩𝐚𝐧𝐲’𝐬 𝐞𝐱𝐢𝐬𝐭𝐢𝐧𝐠 𝐟𝐚𝐜𝐭𝐨𝐫𝐲 𝐩𝐫𝐞𝐦𝐢𝐬𝐞𝐬, which has now been designated as the 𝐍𝐨𝐫𝐭𝐡 𝐂𝐚𝐦𝐩𝐮𝐬 🏭. The South Campus is planned to be utilized for 𝐚𝐝𝐝𝐢𝐭𝐢𝐨𝐧𝐚𝐥 𝐚𝐧𝐜𝐢𝐥𝐥𝐚𝐫𝐲 𝐚𝐧𝐝 𝐬𝐮𝐩𝐩𝐨𝐫𝐭 𝐨𝐩𝐞𝐫𝐚𝐭𝐢𝐨𝐧𝐬.

🚀 More than an addition of physical space, the South Campus has been established as a 𝐬𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐚𝐬𝐬𝐞𝐭, providing the 𝐟𝐥𝐞𝐱𝐢𝐛𝐢𝐥𝐢𝐭𝐲 𝐚𝐧𝐝 𝐫𝐞𝐚𝐝𝐢𝐧𝐞𝐬𝐬 𝐫𝐞𝐪𝐮𝐢𝐫𝐞𝐝 𝐭𝐨 𝐬𝐮𝐩𝐩𝐨𝐫𝐭 𝐟𝐮𝐭𝐮𝐫𝐞 𝐞𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧 in alignment with the Company’s growth strategy and evolving business requirements.

This development represents an important step in strengthening Magna’s infrastructure to support 𝐬𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐥𝐞 𝐠𝐫𝐨𝐰𝐭𝐡, 𝐨𝐩𝐞𝐫𝐚𝐭𝐢𝐨𝐧𝐚𝐥 𝐫𝐞𝐚𝐝𝐢𝐧𝐞𝐬𝐬, 𝐚𝐧𝐝 𝐥𝐨𝐧𝐠 𝐭𝐞𝐫𝐦 𝐯𝐚𝐥𝐮𝐞 𝐜𝐫𝐞𝐚𝐭𝐢𝐨𝐧.

🌟 𝐂𝐡𝐚𝐦𝐩𝐢𝐨𝐧𝐢𝐧𝐠 𝐋𝐞𝐚𝐫𝐧𝐢𝐧𝐠, 𝐋𝐞𝐚𝐝𝐞𝐫𝐬𝐡𝐢𝐩 & 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐄𝐧𝐠𝐚𝐠𝐞𝐦𝐞𝐧𝐭 🌟

🌟 𝐂𝐡𝐚𝐦𝐩𝐢𝐨𝐧𝐢𝐧𝐠 𝐋𝐞𝐚𝐫𝐧𝐢𝐧𝐠, 𝐋𝐞𝐚𝐝𝐞𝐫𝐬𝐡𝐢𝐩 & 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐄𝐧𝐠𝐚𝐠𝐞𝐦𝐞𝐧𝐭 🌟

We take immense pride in recognizing the dedication and industry engagement demonstrated by our team members. Our employees 𝐌𝐫. 𝐊𝐚𝐫𝐭𝐡𝐢𝐤𝐞𝐲𝐚𝐧 𝐀 𝐚𝐧𝐝 𝐌𝐫. 𝐀𝐧𝐚𝐧𝐝𝐚𝐫𝐚𝐣 𝐀 actively participated and won First Prize in the 39th 𝐅𝐨𝐮𝐧𝐝𝐫𝐲 𝐐𝐮𝐢𝐳 𝐂𝐨𝐧𝐭𝐞𝐬𝐭, a prestigious technical knowledge platform organized by The Institute of Indian Foundrymen (IIF), Coimbatore Chapter, and sponsored by M/s 𝐕𝐞𝐥𝐮𝐦𝐚𝐧𝐢 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 (𝐓𝐞𝐱𝐯𝐞𝐥) on 13th December 2025.

👏 We extend our heartfelt appreciation to Mr. Karthikeyan and Mr. Anandaraj for enthusiastically representing our Company. Their commitment to 𝐮𝐩𝐬𝐤𝐢𝐥𝐥𝐢𝐧𝐠 and their 𝐰𝐢𝐥𝐥𝐢𝐧𝐠𝐧𝐞𝐬𝐬 to participate in competitive forums truly make us proud.

🙏 We also express our gratitude to 𝐓𝐡𝐞 𝐈𝐧𝐬𝐭𝐢𝐭𝐮𝐭𝐞 𝐨𝐟 𝐈𝐧𝐝𝐢𝐚𝐧 𝐅𝐨𝐮𝐧𝐝𝐫𝐲𝐦𝐞𝐧 – 𝐂𝐨𝐢𝐦𝐛𝐚𝐭𝐨𝐫𝐞 𝐂𝐡𝐚𝐩𝐭𝐞𝐫 and M/s Velumani Engineering Industry (Texvel) for organizing and supporting such impactful initiatives that inspire technical professionals across the region.

✨ Here’s to many more opportunities where our teams continue to learn, grow, and shine! ✨

🌟 𝐋𝐞𝐚𝐝𝐞𝐫𝐬𝐡𝐢𝐩 𝐀𝐧𝐧𝐨𝐮𝐧𝐜𝐞𝐦𝐞𝐧𝐭 🌟

🌟 𝐋𝐞𝐚𝐝𝐞𝐫𝐬𝐡𝐢𝐩 𝐀𝐧𝐧𝐨𝐮𝐧𝐜𝐞𝐦𝐞𝐧𝐭 🌟

We’re pleased to welcome 𝐌𝐬. 𝐍𝐢𝐯𝐞𝐝𝐢𝐭𝐚 𝐋𝐚𝐤𝐬𝐡𝐦𝐢 𝐍𝐚𝐫𝐚𝐲𝐚𝐧𝐚𝐬𝐰𝐚𝐦𝐲 as 𝐕𝐢𝐜𝐞 𝐏𝐫𝐞𝐬𝐢𝐝𝐞𝐧𝐭 – 𝐅𝐢𝐧𝐚𝐧𝐜𝐞 at Magna Electro Castings Limited, effective 5th January 2026.

With 13+ 𝐲𝐞𝐚𝐫𝐬 𝐨𝐟 𝐠𝐥𝐨𝐛𝐚𝐥 𝐞𝐱𝐩𝐞𝐫𝐢𝐞𝐧𝐜𝐞 across FP&A, strategic finance, and supply chain finance, Ms. Nivedita brings a strong track record of driving data-led decision-making and business impact.

She most recently served as 𝐇𝐞𝐚𝐝 𝐨𝐟 𝐅𝐢𝐧𝐚𝐧𝐜𝐞 – 𝐋𝐮𝐦𝐞 & 𝐌𝐚𝐧𝐝𝐨 𝐚𝐭 𝐌𝐚𝐦𝐦𝐨𝐭𝐡 𝐁𝐫𝐚𝐧𝐝𝐬, leading finance for a 𝐜𝐨𝐫𝐞 𝐛𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐮𝐧𝐢𝐭, and has held 𝐩𝐫𝐨𝐠𝐫𝐞𝐬𝐬𝐢𝐯𝐞 𝐫𝐨𝐥𝐞𝐬 within finance teams at 𝐀𝐛𝐛𝐕𝐢𝐞 𝐚𝐧𝐝 𝐖𝐚𝐥𝐠𝐫𝐞𝐞𝐧𝐬 𝐁𝐨𝐨𝐭𝐬 𝐀𝐥𝐥𝐢𝐚𝐧𝐜𝐞.

A 𝐂𝐆𝐌𝐀, Ms. Nivedita holds an 𝐄𝐱𝐞𝐜𝐮𝐭𝐢𝐯𝐞 𝐌𝐁𝐀 𝐟𝐫𝐨𝐦 𝐂𝐨𝐥𝐮𝐦𝐛𝐢𝐚 𝐁𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐒𝐜𝐡𝐨𝐨𝐥, a 𝐌𝐚𝐬𝐭𝐞𝐫’𝐬 𝐟𝐫𝐨𝐦 𝐈𝐄 𝐁𝐮𝐬𝐢𝐧𝐞𝐬𝐬 𝐒𝐜𝐡𝐨𝐨𝐥, and a 𝐁𝐁𝐀 𝐟𝐫𝐨𝐦 𝐄𝐭𝐡𝐢𝐫𝐚𝐣 𝐂𝐨𝐥𝐥𝐞𝐠𝐞.

We’re excited to welcome her to the leadership team as we continue building for the future.

🌟 𝐋𝐢𝐠𝐡𝐭𝐢𝐧𝐠 𝐭𝐡𝐞 𝐏𝐚𝐭𝐡 𝐭𝐨 𝐕𝐢𝐬𝐢𝐨𝐧 𝐚𝐧𝐝 𝐇𝐨𝐩𝐞 ! “𝓑𝓮𝓬𝓪𝓾𝓼𝓮 𝓮𝓿𝓮𝓻𝔂 𝓻𝓮𝓼𝓽𝓸𝓻𝓮𝓭 𝓼𝓲𝓰𝓱𝓽 𝓲𝓼 𝓪 𝓻𝓮𝓷𝓮𝔀𝓮𝓭 𝓵𝓲𝓯𝓮. 👁️✨

🌟 𝐋𝐢𝐠𝐡𝐭𝐢𝐧𝐠 𝐭𝐡𝐞 𝐏𝐚𝐭𝐡 𝐭𝐨 𝐕𝐢𝐬𝐢𝐨𝐧 𝐚𝐧𝐝 𝐇𝐨𝐩𝐞 !

“𝓑𝓮𝓬𝓪𝓾𝓼𝓮 𝓮𝓿𝓮𝓻𝔂 𝓻𝓮𝓼𝓽𝓸𝓻𝓮𝓭 𝓼𝓲𝓰𝓱𝓽 𝓲𝓼 𝓪 𝓻𝓮𝓷𝓮𝔀𝓮𝓭 𝓵𝓲𝓯𝓮. 👁️✨

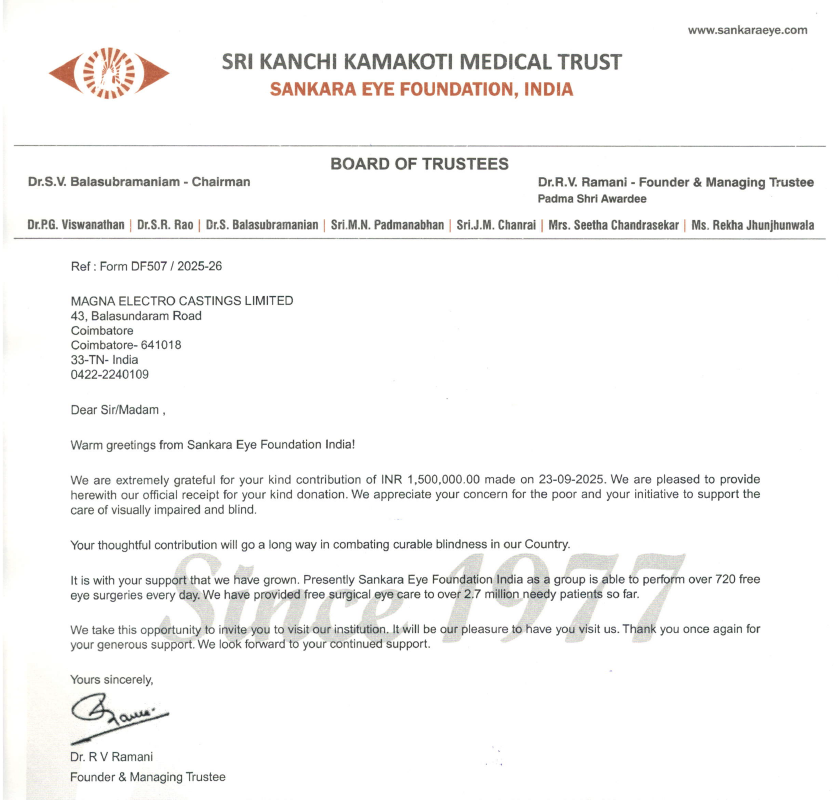

At Magna, we believe progress is meaningful only when it uplifts lives. We’re honoured to partner 🤝 with Sankara Eye Hospitals India (𝐒𝐫𝐢 𝐊𝐚𝐧𝐜𝐡𝐢 𝐊𝐚𝐦𝐚𝐤𝐨𝐭𝐢 𝐌𝐞𝐝𝐢𝐜𝐚𝐥 𝐓𝐫𝐮𝐬𝐭) 🏥, an institution dedicated to 𝐫𝐞𝐬𝐭𝐨𝐫𝐢𝐧𝐠 𝐬𝐢𝐠𝐡𝐭 𝐚𝐧𝐝 𝐡𝐨𝐩𝐞 for underserved communities—working together to bring the 𝐠𝐢𝐟𝐭 𝐨𝐟 𝐯𝐢𝐬𝐢𝐨𝐧 to those who need it most.

💫Through this initiative, Magna’s contribution will be dedicated exclusively to programs that 𝐛𝐞𝐧𝐞𝐟𝐢𝐭 𝐯𝐢𝐬𝐮𝐚𝐥𝐥𝐲 𝐢𝐦𝐩𝐚𝐢𝐫𝐞𝐝 𝐢𝐧𝐝𝐢𝐯𝐢𝐝𝐮𝐚𝐥𝐬, enabling 500 𝐥𝐢𝐟𝐞-𝐜𝐡𝐚𝐧𝐠𝐢𝐧𝐠 𝐞𝐲𝐞 𝐬𝐮𝐫𝐠𝐞𝐫𝐢𝐞𝐬 𝐛𝐲 31 𝐌𝐚𝐫𝐜𝐡 2026. This effort is more than a number—it’s about transforming futures and empowering individuals to see the world anew. 🌍

At Magna MasterCAST, we 𝐥𝐢𝐠𝐡𝐭 𝐭𝐡𝐞 𝐩𝐚𝐭𝐡 𝐭𝐨 𝐜𝐥𝐚𝐫𝐢𝐭𝐲 𝐚𝐧𝐝 𝐡𝐨𝐩𝐞—building a future where vision is accessible to all. 🔆

As we step into this promising year, the 𝐌𝐚𝐠𝐧𝐚 𝐌𝐚𝐬𝐭𝐞𝐫𝐂𝐀𝐒𝐓 team wishes you health, purpose, and progress. 🌱💪 Let’s make 2026 a year of vision, compassion, and shared success. 🎉